DENTAL POLISHING DISCS AND MANDRELS

Polishing discs (Basic UDI-DI 463003499POLDISDH)

##1.021, 1.069, 1.07* series, 1.73* series, 2.07* series, 2.73* series, 9.73* series, 10.73* series

Stem polishing discs (Basic UDI-DI 463003499POLDISDH)

##1.020, 1.6** series, 1.76* series, 9.6** series, 9.76* series, 11.6** series

Mandrels (Basic UDI-DI 463003499MNDDISA7)

##1.110, 1.111, 1.113, 1.115, 1.120, 1.121, 1.121(3), 1.122

INSTRUCTION FOR USE

Revision 14

Revised August 22, 2025

Reason for revision: alignment with (EU) 2021/2226 Regulation requirements

Name of manufacturer

TOR VM Ltd.

Registered trade mark of manufacturer

Address of manufacturer

Novatorov street, 7A, bld.2, room 44B, 119421 Moscow, Russia

SRN RU-MF-000016957

Manufacturing site:

Kulibina, 15c, 394029 Voronezh, Russia

General manager: Dr. Oleg Mikhalev

Technical and manufacturing manager: Dr. Mikhail Lesovoy

Tel.: (495) 225 54 17

e-mail: torvm@gmail.com

internet: www.torvm.ru

European representative

Gregor Kostunov

SRN DE-AR-000006585

Untere Seegasse 54, DE-69124 Heidelberg, Germany

Tel/fax (49) 6221718120

E-mail: tor.vm.de@googlemail.com

The products are CE marked

Notified body

SZUTEST Konformitätsbewertungsstelle GmbH

Notified Body number on NANDO: 2975

Address: Friedrich-Ebert-Anlage 36, 60325 Frankfurt am Main, Germany

Tel.: +49 69 244 333 026

E-Mail: info@szutest-germany.de

Trade names and catalogue numbers

See List of Products (see Annex 1)

General description of the device

Polishing discs with metal connector and stem polishing discs with plastic connector (hereinafter discs) and mandrels are used for polishing and finishing of composite fillings.

Coated abrasive discs are made by bonding abrasive particles onto a thin polymer backing. The discs are coated with an aluminum oxide abrasive or synthetic diamond powder. Normally 4 grades of discs are used: coarse, medium, fine, superfine. The range of particle size distributions noted for coated abrasive discs vary from 100 to 50 micrometers for coarse-grade discs to 15 to 2 micrometers for superfine grade of polishing discs. The grade of disc is coded with disc color.

Mandrels are made from high quality stainless steel and are used to transfer rotation from hand piece to polishing disc.

The devices contain no human or animal-derived tissues or cells.

The devices are supplied non-sterile.

Discs are for single use.

Mandrels can be re-used and must be sterilized after each procedure.

Intended purpose

Polishing and stem polishing discs:

1) to polish dental fillings via rotation transferred from dental hand piece manipulated by dentist;

2) to be used by hand manipulation of hand piece around the dent.

Mandrels:

1) to transfer rotation from dental hand piece to the polishing disc;

2) to be used as intermediate (adapter, transition adapter) between polishing discs and headpiece.

Indications

necessity to polish the restoration after hardening of the restorative material:

to remove excess flash and refine the margins of the restoration, providing smooth restoration contacts and more aesthetic, light-reflectant restoration;

to remove excess of filling material from interproximal areas

Contraindications

Non, dental polishing discs and mandrels can be used for all groups of patients without restrictions

Target groups

Dental polishing discs and mandrels are used for all groups of patients without restrictions, including children (population up to 18 years old).

Intended users

Dental polishing discs (discs) are intended for professional use in dental clinic only. Operating with discs is well known procedure. No special training needed.

Harmonised standards and CS applied

Regulation (EU) 2017/745

EN ISO 14971:2019/A11:2021 Medical devices - Application of risk management to medical devices (ISO 14971:2019)

EN 62366-1:2015/A1:2020 Medical devices – Part 1: Application of usability engineering to medical devices

TU 9391-001-49962851-00 Kits of Dental Polishing Discs of 4 Type of Abrasiveness DSh TOR VM

No incidents, risk-associated cases or non-conformities concerning TOR VM dental polishing discs or equivalent devices have been revealed upon clinical evaluation and clinical post market follow-up study.

Benefits

The main benefits of polishing are:

1. increasing restoration quality and aesthetics,

2. increase restoration service life,

3. reduction of restoration surface roughness,

4. improvement of dentin, composite and ceramics color stability,

5. lowering bacterial adhesion, increasing composite biocompatibility.

Warnings and precautions

1. Do not use discs and mandrels on handpieces intended for speeds exceeding 30000 rpm to avoid the disc or mandrel damage that may lead to an injury.

2. Do not operate mandrel without disc.

3. Avoid contacting of mandrel or disc connector with composite - possible discoloration may require to repeat polishing once more.

4. Use successively discs of all 4 types - otherwise the quality of restoration polishing may be reduced.

5. Control quality of disc surface while operating. Rotational behavior and the appearance of the disc changes 10-15 seconds before separation or break. The visual appearance of the disintegrated disc is changed. Do not use discs with delaminated abrasive coating or damaged polymer part. This may cause tissue damage.

6. Control the cooling air supply during polishing to avoid dentin overheating.

7. Do not use polishing disc once more – discs are single-use device – second use can lead to:

- tissue infection,

- tissue damage caused by delamination of abrasive coating,

- tissue damage by parts of disintegrated disc,

- tissue damage caused by disconnection between disc and mandrel.

8. If package with discs or mandrels is broken or disrupted discs or mandrels prior to use must be sterilized by a standard method.

9. In case of registered accidental contact of device with tooth or soft tissues stop polishing and inspect place of contact for possible damage. In case of soft tissue damage perform corresponding treatment to exclude possible complications

STERILIZATION

Mandrels ##1.110, 1.111, 1.113, 1.115, 1.120, 1.121, 1.121(3), 1.122

Mandrels are sterilized after each patient using conventional steam autoclave at 134°C for 5 minutes.

Presterilizing clearing

In order to remove any inorganic and organic contaminants (including protein, fat, mechanical and others), including drug residues from medical device and to decrease in general microbial contamination to facilitate subsequent sterilization presterilizing clearing is carried out.

The devices can be cleaned in two ways:

a) mechanical cleaning;

b) ultrasonic cleaning.

A. Mechanical cleaning

1) Soak devices with full immersion in the cleaning agent with filling the cavities and channels with cleaning agent right after the use;

2) Wash devices in the same cleaning agent in which it was soaked using a brush;

3) Rinse with running water (channels - using a syringe or electric suction);

4) Rinse with distilled water (channels - using a syringe or electric suction);

It is up to end user to ensure that cleaning agent is suitable for medical devices mechanical cleaning and use it in accordance with its instruction on use.

B. Ultrasonic cleaning

1) Fill the ultrasonic bath container with the devices (collapsible products were placed in disassembled form; products with locks - open), then the cleaning agent was added to at least 1/3 and not more than 2/3 of the volume of the container of the ultrasonic bath;

2) Process in an ultrasonic bath with the temperature of the cleaning agent at least 18°C;

3) Rinse with running water (channels - using a syringe or electric suction);

4) Rinse with distilled water (channels - using a syringe or electric suction);

It is up to end user to ensure that cleaning agent is suitable for use in ultrasonic baths and use it in accordance with its instruction on use.

Sterilization process:

Procedure:

1) Disinfect your hands;

2) Put on disposable gloves;

3) Put the cleaned the devices in the autoclave bag;

4) Carry out the sterilization in accordance with the instruction of the autoclave manufacturer at 134oC for 5 minutes.

Warning:

1) Do not use cleaning agents, detergents or disinfectants containing high percentage of chlorine and cleaners containing oxalic acid, strong alkalines (pH>9), strong acids (pH<4), phenols or iodophors, hydrogen peroxide, interhalogenic agents, halogenic hydrocarbons, strong oxidizing agents, organic solvents, aldehydes.

2) Do not keep mandrels in liquid medium for more than 3 hours.

3) Dry the mandrels thoroughly before sterilization.

4) Follow instructions of autoclave (sterilizer) manufacturer.

5) To avoid corrosion of the metal due to electrolysis, do not place devices in autoclave together with products made of aluminum, brass and copper.

6) Do not use / sterilize the mandrels in case of presence of traces of rust on the surface or traces of surface damage.

Polishing discs ##1.021, 1.069, 1.07* series, 1.73* series, 2.07* series, 2.73* series, 9.73* series, 10.73* series

Stem polishing discs ##1.020, 1.6** series, 1.76* series, 9.6** series, 9.76* series, 11.6** series

In case of risk of disc contamination discs can be sterilized using conventional steam autoclave at 121°C for 20 minutes.

Operating instructions

Preparation

1. Open the packaging.

2. Make sure that there are no:

- signs of violation of the integrity of the device (including cracks and chips),

- traces of rust or dirt on the surface.

Operating procedure

1. Remove excess composite and contour the restoration using a fine diamond or carbide bur.

2. Accurately open the package with discs to avoid squabbling and mixing of the discs and choose disc for gross reduction of necessary diameter.

3. Place disc for gross reduction by gentle pushing of the connector onto preliminary sterilized mandrel until the disc is secure connected (disc must not wobble on mandrel).

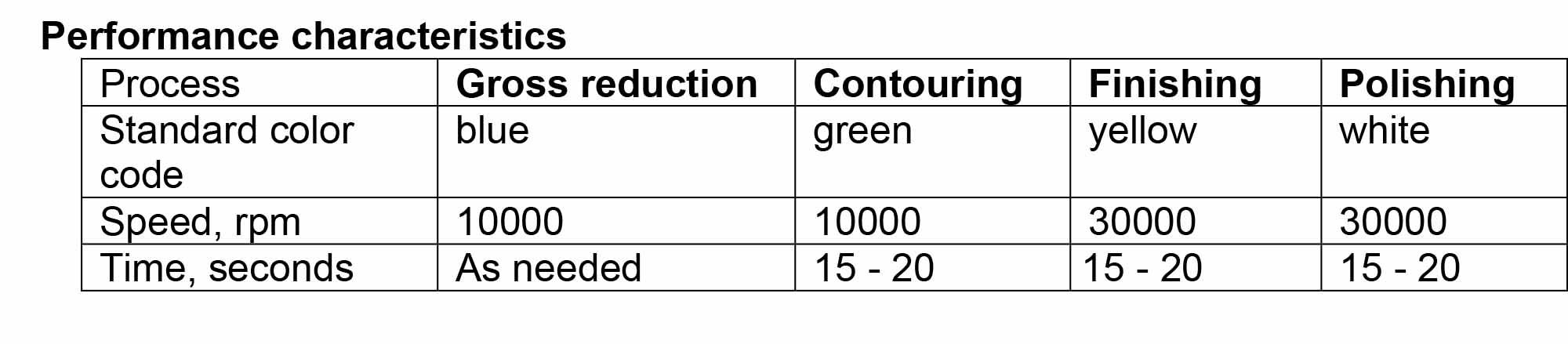

4. Start polishing at a speed not more than 10000 rpm. (speed and duration when using disc of another type see the Table)

5. When the polishing is finished wash away the residuals of polishing.

6. Remove the gross reduction disc from mandrel by positioning a thumbnail under the disc connector and pushing the disc away from the mandrel.

7. Place disc for contouring by gentle pushing of the connector onto mandrel until the disc is secure (disc must not wobble on mandrel) and repeat procedures 3 – 4 taking into account changed abrasiveness of the disc (see the Table).

When polishing pay attention to:

a. move in one direction: from gingiva towards restoration (back and forth movement over the composite-enamel margin is not recommended);

b. use light pressure;

c. keep the restoration surface and disc dry when polishing to reach more smooth and uniform effect;

d. cool the polished tooth with air to avoid dentin overheating.

Storage

Store discs and mandrels in a dry place.

Store discs away from direct sunlight. The storage at direct light can cause disc color change and flexibility decrease.

Discs and mandrels in plastic packages should be stored away from heating devices to avoid packaging damage.

Product shelf-life

Shelf-life of discs is 5 years since date of production.

Shelf-life of mandrels is unlimited.

Disposal

Used discs and unusable mandrels are to be disposed as class 3a "other non-hazardous wastes" according to WHO-UNEP/SBC 2005 coding

recommendations.

Warranty

Warranty time for mandrels is 1 year after the first use (guaranteed number of allowable reuses is 200).

Discs are single-use devices.

TOR VM will replace the product that is proved to be nonconforming.

It is up to user to ensure that the product is suitable for the intended process and purpose.

Any serious incident or non-compliance that has occurred in relation to TOR VM discs and/or mandrels should be reported by e-mail torvm77@gmail.com and/or tor.vm.de@googlemail.com.

In case of emergency (any serious incident that has occurred in relation to the device) please, contact

TOR VM

Tel.: (495) 225 54 17

e-mail: torvm@gmail.com

European representative

Gregor Kostunov

Tel/fax (49) 6221718120

E-mail: tor.vm.de@googlemail.com

Language

IFU is available in English and can be provided in any official Union language on customer request.

If you need IFU paper version, please contact

TOR VM

Tel.: (495) 225 54 17

e-mail: torvm@gmail.com

European representative

Gregor Kostunov

Tel/fax (49) 6221718120

E-mail: tor.vm.de@googlemail.com

|